新乡水泵有限公司

电话:0373-7722288

手机:132 3383 5625

155 3833 3888

网址:www.rqpump.com

地址:新乡延津县产业集聚区纬七路东段

一、产品概述

iswb卧式单级单吸防爆油泵,是在isw基础上派声生出适用油泵。该系列泵性能优、可靠性高、寿命长、结构合理、 外形美观,具有行业领 先水平。

二、产品特点

运行平稳:泵轴的绝 对同心度及叶轮优异的动静平衡,保证平稳运行,无振动。

滴水不漏:不同材质的硬质合金密封,保证了不同介质输送均无泄漏。

噪音低:两个低噪音轴承支撑下的水泵,运转平稳,除电机微弱声响,基本无噪音。

故障率低:结构简单合理,关键部分采用国际一 流品质;配套,整机无故障工作时间大大提高。

维修方便:更换密封、轴承,简易方便。

占地更省:出口可向左、向右、向上三个方向,便于管道布置安装,节省空间。

三、主要用途

iswb卧式单级单吸防爆油泵,供输送汽油、煤油、柴油等石油产品,被输送介质温度为-20℃~ 105℃。

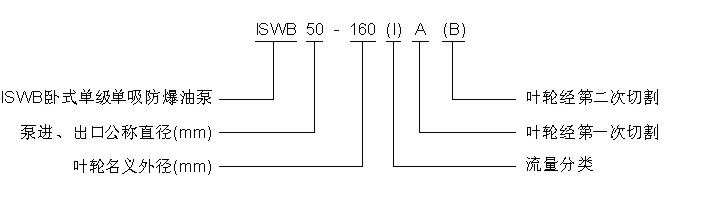

四、型号意义

型号 | 流量 | 扬程 | 功率 | 电压 | ||

m3/h | m | kw | v | |||

15-80 | 1.5 | 8 | 0.18-2 | 220 | ||

20-110 | 2.5 | 15 | 0.37-2 | 220/380 | ||

20-125 | 2.5 | 20 | 0.75-2 | 200/380 | ||

20-160 | 2.5 | 32 | 1.1-2 | 220/380 | ||

25-110 | 4 | 15 | 0.75-2 | 220/380 | ||

25-125 | 4 | 20 | 0.75-2 | 220/380 | ||

25-125a | 3.6 | 16 | 0.75-2 | 220/380 | ||

25-160 | 4 | 32 | 1.5-2 | 380 | ||

25-160a | 3.7 | 28 | 1.1-2 | 380 | ||

32-100 | 4.5 | 12.5 | 0.55-2 | 220/380 | ||

32-125 | 5 | 20 | 0.75-2 | 220/380 | ||

32-125a | 4.5 | 16 | 0.75-2 | 220/380 | ||

32-160 | 5 | 32 | 1.5-2 | 380 | ||

32-160a | 4.5 | 25 | 1.1-2 | 380 | ||

32-160(i) | 6.3 | 32 | 2.2-2 | 380 | ||

32-200 | 5 | 50 | 3-2 | 380 | ||

32-200a | 4.5 | 44 | 2.2-2 | 380 | ||

32-200b | 3.5 | 38 | 1.5-2 | 380 | ||

32-200(i) | 6.3 | 50 | 4-2 | 380 | ||

40-100 | 6.3 | 12.5 | 0.75-2 | 220/380 | ||

40-100a | 5.6 | 10 | 0.75-2 | 220/380 | ||

40-125 | 6.3 | 20 | 1.1-2 | 220/380 | ||

40-125a | 5.6 | 16 | 0.75-2 | 220/380 | ||

40-160 | 6.3 | 32 | 2.2-2 | 380 | ||

40-160a | 5.9 | 28 | 1.5-2 | 380 | ||

40-160b | 5.5 | 24 | 1.1-2 | 380 | ||

40-200 | 6.3 | 50 | 4-2 | 380 | ||

40-200a | 5.9 | 44 | 3-2 | 380 | ||

40-200b | 5.3 | 36 | 2.2-2 | 380 | ||

40-250 | 6.3 | 80 | 7.5-2 | 380 | ||

40-250a | 5.9 | 70 | 5.5-2 | 380 | ||

40-250b | 5.5 | 60 | 4-2 | 380 | ||

40-100(i) | 12.5 | 12.5 | 1.1-2 | 380 | ||

40-100(i)a | 11 | 10 | 0.75-2 | 380 | ||

40-125(i) | 12.5 | 20 | 1.5-2 | 380 | ||

40-125(i)a | 11 | 16 | 1.1-2 | 380 | ||

40-160(i) | 12.5 | 32 | 3-2 | 380 | ||

40-160(i)a | 11.7 | 28 | 2.2-2 | 380 | ||

40-160(i)b | 10.4 | 22 | 1.5-2 | 380 | ||

40-200(i) | 12.5 | 50 | 5.5-2 | 380 | ||

40-200(i)a | 11.7 | 44 | 4-2 | 380 | ||

40-200(i)b | 10.6 | 36 | 3-2 | 380 | ||

40-250(i) | 12.5 | 80 | 11-2 | 380 | ||

40-250(i)a | 11.6 | 70 | 7.5-2 | 380 | ||

40-250(i)b | 10.8 | 60 | 5.5-2 | 380 | ||

40-250 (i) c | 10 | 52 | 5.5-2 | 380 | ||

50-100 | 12.5 | 12.5 | 1.1-2 | 380 | ||

50-100a | 11 | 10 | 0.75-2 | 380 | ||

50-125 | 12.5 | 20 | 1.5-2 | 380 | ||

50-125a | 11 | 16 | 1.1-2 | 380 | ||

50-160 | 12.5 | 32 | 3-2 | 380 | ||

50-160a | 11.7 | 28 | 2.2-2 | 380 | ||

50-160b | 10.4 | 22 | 1.5-2 | 380 | ||

50-200 | 12.5 | 50 | 5.5-2 | 380 | ||

50-200a | 11.7 | 44 | 4-2 | 380 | ||

50-200b | 10.6 | 36 | 3-2 | 380 | ||

50-250 | 12.5 | 80 | 11-2 | 380 | ||

50-250a | 11.6 | 70 | 7.5-2 | 380 | ||

50-250b | 10.8 | 60 | 7.5-2 | 380 | ||

50-250c | 10 | 52 | 5.5-2 | 380 | ||

50-100(i) | 25 | 12.5 | 1.5-2 | 380 | ||

50-100(i)a | 22.3 | 10 | 1.1-2 | 380 | ||

50-125(i) | 25 | 20 | 3-2 | 380 | ||

50-125(i)a | 22.3 | 16 | 2.2-2 | 380 | ||

50-160(i) | 25 | 32 | 4-2 | 380 | ||

50-160(i)a | 23.4 | 28 | 3-2 | 380 | ||

50-160(i)b | 21.6 | 24 | 2.2-2 | 380 | ||

50-200(i) | 25 | 50 | 7.5-2 | 380 | ||

50-200(i)a | 23.5 | 44 | 5.5-2 | 380 | ||

50-200(i)b | 21.8 | 38 | 4-2 | 380 | ||

50-250(i) | 25 | 80 | 15-2 | 380 | ||

50-250(i)a | 23.4 | 70 | 11-2 | 380 | ||

50-250(i)b | 21.6 | 60 | 7.5-2 | 380 | ||

50-315(i) | 25 | 125 | 30-2 | 380 | ||

50-315(i)a | 23.7 | 113 | 22-2 | 380 | ||

50-315(i)b | 22.5 | 101 | 18.5-2 | 380 | ||

50-315(i)c | 20.6 | 85 | 15-2 | 380 | ||

65-100 | 25 | 12.5 | 1.5-2 | 380 | ||

65-100a | 22.3 | 10 | 1.1-2 | 380 | ||

65-125 | 25 | 20 | 3-2 | 380 | ||

65-125a | 22.3 | 16 | 2.2-2 | 380 | ||

65-160 | 25 | 32 | 4-2 | 380 | ||

65-160a | 23.4 | 28 | 3-2 | 380 | ||

65-160b | 21.6 | 24 | 2.2-2 | 380 | ||

65-200 | 25 | 50 | 7.5-2 | 380 | ||

65-200a | 23.5 | 44 | 5.5-2 | 380 | ||

65-200b | 21.8 | 38 | 4-2 | 380 | ||

65-250 | 25 | 80 | 15-2 | 380 | ||

65-250a | 23.4 | 70 | 11-2 | 380 | ||

65-250b | 21.6 | 60 | 7.5-2 | 380 | ||

65-315 | 25 | 125 | 30-2 | 380 | ||

65-315a | 23.7 | 113 | 22-2 | 380 | ||

65-315b | 22.5 | 101 | 18.5-2 | 380 | ||

65-315c | 20.6 | 85 | 15-2 | 380 | ||

65-100(i) | 50 | 12.5 | 3-2 | 380 | ||

65-100(i)a | 44.7 | 10 | 2.2-2 | 380 | ||

65-125(i) | 50 | 20 | 5.5-2 | 380 | ||

65-125(i)a | 45 | 16 | 4-2 | 380 | ||

65-160(i) | 50 | 32 | 7.5-2 | 380 | ||

65-160(i)a | 46.7 | 28 | 5.5-2 | 380 | ||

65-160(i)b | 43.3 | 24 | 4-2 | 380 | ||

65-200(i) | 50 | 50 | 15-2 | 380 | ||

65-200(i)a | 47 | 44 | 11-2 | 380 | ||

65-200(i)b | 43.5 | 38 | 7.5-2 | 380 | ||

65-250(i) | 50 | 80 | 22-2 | 380 | ||

65-250(i)a | 46.7 | 70 | 18.5-2 | 380 | ||

65-250(i)b | 43.3 | 60 | 15-2 | 380 | ||

65-315(i) | 50 | 125 | 37-2 | 380 | ||

65-315(i)a | 46.5 | 110 | 30-2 | 380 | ||

65-315(i)b | 44.5 | 100 | 30-2 | 380 | ||

65-315(i)c | 41 | 85 | 22-2 | 380 | ||

80-100 | 50 | 12.5 | 3-2 | 380 | ||

80-100a | 44.7 | 10 | 2.2-2 | 380 | ||

80-125 | 50 | 20 | 5.5-2 | 380 | ||

80-125a | 45 | 16 | 4-2 | 380 | ||

80-160 | 50 | 32 | 7.5-2 | 380 | ||

80-160a | 46.7 | 28 | 5.5-2 | 380 | ||

80-160b | 43.3 | 24 | 4-2 | 380 | ||

80-200 | 50 | 50 | 15-2 | 380 | ||

80-200a | 47 | 44 | 11-2 | 380 | ||

80-200b | 43.5 | 38 | 7.5-2 | 380 | ||

80-250 | 50 | 80 | 22-2 | 380 | ||

80-250a | 46.7 | 70 | 18.5-2 | 380 | ||

80-250b | 43.3 | 60 | 15-2 | 380 | ||

80-315 | 50 | 125 | 37-2 | 380 | ||

80-315a | 46.5 | 110 | 30-2 | 380 | ||

80-315b | 44.5 | 100 | 30-2 | 380 | ||

80-315c | 41 | 85 | 22-2 | 380 | ||

80-100(i) | 100 | 12.5 | 5.5-2 | 380 | ||

80-100(i)a | 89 | 10 | 4-2 | 380 | ||

80-125(i) | 100 | 20 | 11-2 | 380 | ||

80-125(i)a | 89 | 16 | 7.5-2 | 380 | ||

80-160(i) | 100 | 32 | 15-2 | 380 | ||

80-160(i)a | 93.5 | 28 | 11-2 | 380 | ||

80-160(i)b | 86.6 | 24 | 7.5-2 | 380 | ||

80-200(i) | 100 | 50 | 22-2 | 380 | ||

80-200(i)a | 93.5 | 44 | 18.5-2 | 380 | ||

80-200(i)b | 87 | 38 | 15-2 | 380 | ||

80-200(i) | 100 | 50 | 22-2 | 380 | ||

80-250(i) | 100 | 80 | 37-2 | 380 | ||

80-250(i)a | 93.5 | 70 | 30-2 | 380 | ||

80-250(i)b | 87 | 60 | 30-2 | 380 | ||

80-315(i) | 100 | 125 | 75-2 | 380 | ||

80-315(i)a | 95 | 113 | 55-2 | 380 | ||

80-315(i)b | 90 | 101 | 45-2 | 380 | ||

80-315(i)c | 82 | 85 | 37-2 | 380 | ||

100-100 | 100 | 12.5 | 5.5-2 | 380 | ||

100-100a | 89 | 10 | 4-2 | 380 | ||

100-125 | 100 | 20 | 11-2 | 380 | ||

100-125a | 89 | 16 | 7.5-2 | 380 | ||

100-160 | 100 | 32 | 15-2 | 380 | ||

100-160a | 93.5 | 28 | 11-2 | 380 | ||

100-160b | 86.6 | 24 | 7.5-2 | 380 | ||

100-200 | 100 | 50 | 22-2 | 380 | ||

100-200a | 93.5 | 44 | 18.5-2 | 380 | ||

100-200b | 87 | 38 | 15-2 | 380 | ||

100-250 | 100 | 80 | 37-2 | 380 | ||

100-250a | 93.5 | 70 | 30-2 | 380 | ||

100-250b | 87 | 60 | 30-2 | 380 | ||

100-315 | 100 | 125 | 75-2 | 380 | ||

100-315a | 95 | 113 | 55-2 | 380 | ||

100-315b | 90 | 101 | 45-2 | 380 | ||

100-315c | 82 | 85 | 37-2 | 380 | ||

100-100(i) | 160 | 12.5 | 11-2 | 380 | ||

100-125(i) | 160 | 20 | 15-2 | 380 | ||

100-125(i)a | 140 | 17 | 11-2 | 380 | ||

100-160(i) | 160 | 32 | 22-2 | 380 | ||

100-160(i)a | 140 | 28 | 18.5-2 | 380 | ||

100-200(i) | 160 | 50 | 37-2 | 380 | ||

100-200(i)a | 140 | 45 | 30-2 | 380 | ||

100-200(i)b | 100 | 40 | 22-2 | 380 | ||

100-250(i) | 160 | 80 | 55-2 | 380 | ||

100-250(i)a | 140 | 72 | 45-2 | 380 | ||

100-250(i)b | 100 | 65 | 37-2 | 380 | ||

100-315(i) | 160 | 125 | 90-2 | 380 | ||

100-315(i)a | 140 | 110 | 75-2 | 380 | ||

100-315(i)b | 100 | 100 | 75-2 | 380 | ||

125-100 | 160 | 12.5 | 11-2 | 380 | ||

125-100a | 143 | 10 | 7.5-2 | 380 | ||

125-125 | 160 | 20 | 15-2 | 380 | ||

125-125a | 143 | 16 | 11-2 | 380 | ||

125-160 | 160 | 32 | 22-2 | 380 | ||

125-160a | 150 | 28 | 18.5-2 | 380 | ||

125-160b | 138 | 24 | 15-2 | 380 | ||

125-200 | 160 | 50 | 37-2 | 380 | ||

125-200a | 150 | 44 | 30-2 | 380 | ||

125-200b | 138 | 37.5 | 22-2 | 380 | ||

125-250 | 160 | 80 | 55-2 | 380 | ||

125-250a | 150 | 70 | 45-2 | 380 | ||

125-250b | 138 | 60 | 37-2 | 380 | ||

125-315 | 160 | 125 | 90-2 | 380 | ||

125-315a | 150 | 110 | 75-2 | 380 | ||

125-315b | 143 | 100 | 75-2 | 380 | ||

125-315c | 134 | 88 | 55-2 | 380 | ||

150-125 | 160 | 20 | 15-2 | 380 | ||

150-125a | 150 | 16 | 11-2 | 380 | ||

150-160 | 160 | 32 | 22-2 | 380 | ||

150-160a | 150 | 28 | 18.5-2 | 380 | ||

150-160b | 140 | 24 | 15-2 | 380 | ||

150-200 | 200 | 12.5 | 15-4 | 380 | ||

150-200a | 179 | 10 | 11-4 | 380 | ||

150-200b | 160 | 8 | 7.5-4 | 380 | ||

150-250 | 200 | 20 | 18.5-4 | 380 | ||

150-250a | 184.4 | 17 | 15-4 | 380 | ||

150-250b | 167 | 14 | 11-4 | 380 | ||

150-315 | 200 | 32 | 30-4 | 380 | ||

150-315a | 187 | 28 | 22-4 | 380 | ||

150-315b | 173 | 24 | 18.5-4 | 380 | ||

150-400 | 200 | 50 | 45-4 | 380 | ||

150-400a | 187 | 44 | 37-4 | 380 | ||

150-400b | 174 | 38 | 30-4 | 380 | ||

150-400c | 160 | 32 | 22-4 | 380 | ||

150-500 | 200 | 80 | 90-4 | 380 | ||

150-500a | 182 | 70.5 | 75-4 | 380 | ||

150-500b | 166 | 62 | 55-4 | 380 | ||

150-250(i) | 200 | 80 | 75-2 | 380 | ||

150-250(i)a | 187 | 70 | 55-2 | 380 | ||

150-250(i)b | 173 | 60 | 45-2 | 380 | ||

150-315(i) | 200 | 125 | 110-2 | 380 | ||

150-315(i)a | 187 | 110 | 90-2 | 380 | ||

150-315(i)b | 173 | 95 | 75-2 | 380 | ||

200-200 | 200 | 12.5 | 15-4 | 380 | ||

200-200a | 179 | 10 | 11-4 | 380 | ||

200-250 | 200 | 20 | 18.5-4 | 380 | ||

200-250a | 184.4 | 17 | 15-4 | 380 | ||

200-250b | 167 | 14 | 11-4 | 380 | ||

200-315 | 200 | 32 | 30-4 | 380 | ||

200-315a | 189 | 28 | 22-4 | 380 | ||

200-315b | 173 | 24 | 18.5-4 | 380 | ||

200-400 | 200 | 50 | 45-4 | 380 | ||

200-400a | 187 | 44 | 37-4 | 380 | ||

200-400b | 174 | 38 | 30-4 | 380 | ||

200-400c | 160 | 32 | 22-4 | 380 | ||

200-500 | 200 | 80 | 90-4 | 380 | ||

200-500a | 182 | 70.5 | 75-4 | 380 | ||

200-500b | 166 | 62 | 55-4 | 380 | ||

200-200(i ) | 400 | 12.5 | 22-4 | 380 | ||

200-200(i )a | 358 | 10 | 18.5-4 | 380 | ||

200-250(i ) | 400 | 20 | 30-4 | 380 | ||

200-250(i )a | 358 | 16 | 22-4 | 380 | ||

200-250(i )b | 322 | 13 | 18.5-4 | 380 | ||

200-315(i ) | 400 | 32 | 55-4 | 380 | ||

200-315(i )a | 374 | 28 | 45-4 | 380 | ||

200-315(i )b | 346 | 24 | 37-4 | 380 | ||

200-400(i) | 400 | 50 | 75-4 | 380 | ||

200-400(i)a | 374 | 44 | 75-4 | 380 | ||

200-400(i)b | 346 | 38 | 45-4 | 380 | ||

200-400(i)c | 320 | 32 | 45-4 | 380 | ||

200-500(i) | 400 | 80 | 132-4 | 380 | ||

200-500(i)a | 374 | 70 | 110-4 | 380 | ||

200-500(i)b | 346 | 60 | 90-4 | 380 | ||

200-500(i)c | 320 | 50 | 75-4 | 380 | ||

250-250 | 550 | 20 | 45-4 | 380 | ||

250-250a | 500 | 17 | 37-4 | 380 | ||

250-315 | 550 | 32 | 75-4 | 380 | ||

250-315a | 500 | 28 | 55-4 | 380 | ||

250-315b | 450 | 24 | 45-4 | 380 | ||

250-400 | 550 | 50 | 110-4 | 380 | ||

250-400a | 500 | 44 | 90-4 | 380 | ||

250-400b | 460 | 38 | 75-4 | 380 | ||

250-400c | 429 | 31 | 55-4 | 380 | ||

250-500 | 550 | 80 | 185-4 | 380 | ||

250-500a | 510 | 70 | 160-4 | 380 | ||

250-500b | 470 | 60 | 132-4 | 380 | ||

250-500c | 430 | 50 | 110-4 | 380 | ||

300-250 | 720 | 20 | 55-4 | 380 | ||

300-250a | 700 | 17 | 45-4 | 380 | ||

300-250b | 600 | 12.5 | 37-4 | 380 | ||

300-315 | 720 | 32 | 90-4 | 380 | ||

300-315a | 637 | 28 | 75-4 | 380 | ||

300-315b | 563 | 24 | 55-4 | 380 | ||

300-400 | 720 | 50 | 132-4 | 380 | ||

300-400a | 662 | 44 | 110-4 | 380 | ||

300-400b | 609 | 38 | 90-4 | 380 | ||

300-400c | 536 | 31 | 75-4 | 380 | ||

300-500 | 720 | 80 | 250-4 | 380 | ||

300-500a | 675 | 70 | 200-4 | 380 | ||

300-500b | 625 | 60 | 160-4 | 380 | ||

300-500c | 570 | 50 | 110-4 | 380 | ||

350-250 | 1200 | 20 | 90-4 | 380 | ||

350-250a | 1080 | 16 | 75-4 | 380 | ||

350-315 | 1200 | 32 | 160-4 | 380 | ||

350-315a | 1120 | 28 | 132-4 | 380 | ||

350-315b | 1040 | 24 | 110-4 | 380 | ||

350-400 | 1200 | 50 | 250-4 | 380 | ||

350-400a | 1120 | 44 | 220-4 | 380 | ||

350-400b | 1040 | 38 | 200-4 | 380 | ||

350-400c | 905 | 31 | 160-4 | 380 | ||

技术参数

流量;1.1-108m3/h

扬程:7-133m

转速:970-2900r/min

工作条件

1、吸入压力≤1.0mpa,或泵系统最高工作压力≤1.6mpa,即泵吸入口压力 泵扬程≤1.6mpa、泵静压试验压力为2.5mpa,订货时请注明系统工作压力。泵系统工作压力大于1.6mpa时应在订货时另行提出。以便在制造时泵的过流部分和联接部分采用铸钢材料。

2、环境温度<40℃,相对湿度<95%。

3、所输送介质中固本颗粒体积含量不超过单位体积的0.1%,粒度<0.2mm。

注:如使用介质为带有细小颗粒,请在订货时注明,以便厂家采用耐磨式机械密封。

起动前的准备

1、试验电机转向是否正确,从电机顶部往泵看为顺时针旋转,试验时间要短,以免使机械密封干磨损。

2、打开排气阀使液体充满整个泵体,待满后关闭排气阀。

3、检查各部位是否正常。

4、用手盘动泵以使润滑液进入机械密封端面。

5、高温型应先进行预热,升温速度50℃/小时,以保证各部受热均匀。

起动:

1、全开进口阀门。

2、关闭吐出管路阀门。

3、起动电机,观察泵运行是否正确。

4、调节出口阀门开度以所需工况,如用户在泵出口处装有流量表或压力表,应通过调节出口阀门开度使泵在性能参数表所列的额定点上运转,如用户在泵出口处装有流量表或压力表,应通过调节出口阀门开度,测量泵的电机电流,使电机在额定电流内运行,否则将造成泵超负荷运行(即大电流运行)至使电机烧坏。调正好的出口阀门开启大与小和管道工况有关。

5、检查轴封泄漏情况,正常时机械密封泄漏应小于3滴/分。

6、检查电机、轴承处温升≤70℃。

停车:

1、高温型先降温,降温速度<10℃/分,把温度降低到80℃以下,才能停车。

2、关闭吐出管路阀门。

3、停止电机。

4、关闭进口阀门。

5、如长期停车,应将泵内液体放尽。